HVOF / Thermal Spray Coatings

Extend part reliability up to 4x longer than spray welding and metalizing.

Spray welding and metalizing have caused lots of frustration over the years in our industry. So when Vail saw the superior performance of thermal spray coating — combustion wire, combustion powder and high Velocity Oxy-Fuel (HVOF) surface technologies — we knew we had to make it available to you.

The in-the-field results of thermal spray coatings on rolls are amazing. Many customers have increased the run times between routine maintenance of their roll journals, cores and other equipment by up to four times in some of the roughest, most corrosive and extreme conditions. That extended up time translates to significant production dollars and reduced maintenance budgets.

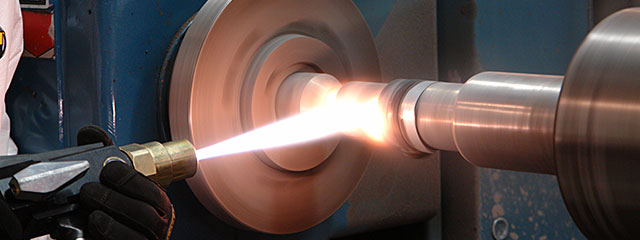

Here is how thermal spraying can improve your rolls' reliability. Using a supersonic flame, our thermal spray coating specialists shoot an HVOF spray of metallic particles onto the surface of your roll parts. This technology:

- Lets us do dimensional repairs faster than roll welds, plates or sleeves.

- Applies to any substrate without warping, distorting, diffusion or annealing

- Resists corrosion, impact and erosion with a hardness up to Rc72.

- Goes on smoother, so there's minimal grinding; lets you get a mirror finish.

- Is an environmentally responsible process, unlike chrome plating that can pollute the air, landfills and nearby waterways.

Thermal spray is an economical solution for roll parts that need frequent recoating or maintenance.

To ensure that your roll part will last longer, our thermal spray coating specialists will first perform a surface analysis. They'll then recommend the best roll coating from more than 300 options so you start seeing better-cost controls. Vail's Surface Technology Center in-house services include:

- Precision machining and grinding

- Part pick up and delivery

- Emergency response

- Fast turnarounds that reduce costly downtime

For a tour or more information about how we can make your parts last longer, call 877-350-0441 or email us today