Custom Engineered Covers

Vail's Technical Service team will help you choose the correct cover, finish and profile every time.

The Vail Technical Service team has extensive experience in custom engineering the correct roll covers for almost every roll application. With our custom formulation capabilities and in-house mixing facility, we can meet your specific needs and ensure that every roll we deliver passes our high quality requirements. You can count on Vail to develop roll covers that perform better, last longer and keep costs lower because our team:

- Monitors industry trends so we can anticipate changing roll cover needs

- Performs customer site evaluations of your process conditions and existing roll life so you get the correct tolerances for your application

- Listens to your process and roll cover concerns and responds with performance-improving and cost-saving solutions

- Analyzes roll performance per unit of production

- Conducts chemical resistance testing with your chemicals

- Inspects incoming covers and cores and analyzes the effects of load and speed on them

- Specifies correct elastomer hardness from bone hard to extra soft

- Offers the right surface finish from polished, belt or wheel grind, threaded or crepe, no-slip and custom options

- Provides precision drilling, beveling and grooving (diamond, herringbone or Chevron, spiral, circumferential cuts or grooves, razor cut/cubed and Venta-nip)

- Builds new cores to your specifications

So whether you are manufacturing a new product, looking for ways to lower costs on an existing line or dealing with an environment that's destroying your roll maintenance budget —bring the challenge to us. We are your one-stop problem solver.

Roll Maintenance

Return your rolls to like-new condition.

Even Vail's longer-lasting, more reliable roll covers and cores eventually need refurbishing or repair. So whether it's a Vail roll cover or one of our competitor's that needs work, our Mechanical Service team will focus on getting your rolls quickly returned to your line and ready to perform at peak efficiency. Contact us for:

- Regrinding or recovering your rolls

- Grooving and beveling

- Precision drilling to clean plugged cores and shells

- Cover surface and core inspections (including non-destructive testing)

- Metal core repair and millwright services

- Rebuilding and reconditioning of suction boxes

- Headbox apron and top slice up refurbishment

- Variable crown refurbishment

- Thermal spray coating for roll journals, cores and other equipment

- Fast delivery of spare parts

- Roll cover maintenance and care seminars

Whether you are manufacturing a new product, looking for ways to lower costs on an existing line or dealing with an environment that's destroying your roll maintenance budget —bring the challenge to us. We are your one-stop problem solver.

Learn more about Vail's full-service roll maintenance:

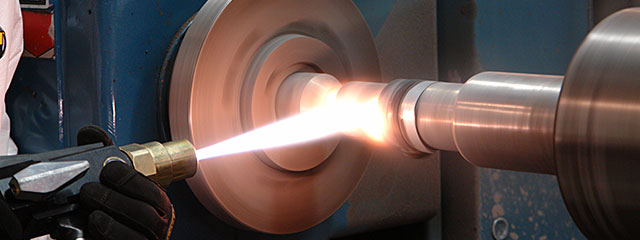

HVOF / Thermal Spray Coatings

Extend part reliability up to 4x longer than spray welding and metalizing.

Spray welding and metalizing have caused lots of frustration over the years in our industry. So when Vail saw the superior performance of thermal spray coating — combustion wire, combustion powder and high Velocity Oxy-Fuel (HVOF) surface technologies — we knew we had to make it available to you.

The in-the-field results of thermal spray coatings on rolls are amazing. Many customers have increased the run times between routine maintenance of their roll journals, cores and other equipment by up to four times in some of the roughest, most corrosive and extreme conditions. That extended up time translates to significant production dollars and reduced maintenance budgets.

Here is how thermal spraying can improve your rolls' reliability. Using a supersonic flame, our thermal spray coating specialists shoot an HVOF spray of metallic particles onto the surface of your roll parts. This technology:

- Lets us do dimensional repairs faster than roll welds, plates or sleeves.

- Applies to any substrate without warping, distorting, diffusion or annealing

- Resists corrosion, impact and erosion with a hardness up to Rc72.

- Goes on smoother, so there's minimal grinding; lets you get a mirror finish.

- Is an environmentally responsible process, unlike chrome plating that can pollute the air, landfills and nearby waterways.

Thermal spray is an economical solution for roll parts that need frequent recoating or maintenance.

To ensure that your roll part will last longer, our thermal spray coating specialists will first perform a surface analysis. They'll then recommend the best roll coating from more than 300 options so you start seeing better-cost controls. Vail's Surface Technology Center in-house services include:

- Precision machining and grinding

- Part pick up and delivery

- Emergency response

- Fast turnarounds that reduce costly downtime

For a tour or more information about how we can make your parts last longer, call 877-350-0441 or email us today

Other Services

Vail specialty products, FREE roll analysis and fast delivery keep your production lines making money.

The roll is just one part of your process, but when it's not running at peak performance you can lose money. Vail roll cover specialists take pride in helping you control your costs by being your source for:

- Mandrel sleeves that create less scrap. Our Technical Services team carefully engineers the sleeves so they can withstand the pressure, torque, temperature and chemicals in your operation — a significant advantage when you are processing oiled and highly surface-critical metal sheets. Our designs help to eliminate excessive coil end break, telescoping and side dishing. Contact us to learn what Vail mandrel sleeve design will improve your operations.

- Urethane pads and products to protect your rolls and surface-critical metals. Vail offers a variety of urethane products: crane coil sheaths and hooks, coil and conveyor pads, bumpers, mounts, spacer rings, floor pads and other parts. We also custom design and manufacturer high quality urethane products for proprietary and special applications.

- Masroll® rolls that quickly and efficiently remove fluids. When you need to remove liquids from your process — whether it is water, oil, hydrocarbon solvents, plasticizers, acid, alkaline or other liquid chemicals — this revolutionary micro-fiber roll pad and vacuum suction system does an outstanding job of absorbing liquids. In some instances, it can actually eliminate the need for a dryer (a significant equipment and energy savings). To see if this liquid processing system is a solution for your operations, contact us.

- FREE, onsite roll analysis. At Vail there is no guessing what will work best in in your operation. No off-the-shelf solutions, either. Instead, we'll send our field support team to your site to conduct a thorough analysis of your rolls and your operating environment. It's a no-obligation way to see whether you can cut costs and improve your processes. To learn more or to schedule an analysis, click here.

- Fast deliveries. Customers tell us that often our repairs, refurbishments and even our new roll covers arrive in the time others charge for "rush" services. At Vail, we provide roll cover solutions for companies anywhere in the continental United States and some provinces of Canada. We operate our own fleet of trucks to expedite transporting rolls in the Midwest and Southeast. Other locations get timely deliveries from our common carriers. And if our fast delivery schedule isn't fast enough, rush deliveries are available. Talk to us and let's get you the turnaround you need.

Technical and Mechanical Services

Get custom solutions for your unique roll cover demands.

In our more than 100 years of making roll covers, we have yet to find any two customers whose processes, equipment, environment and employees are exactly the same. Your situation is unique, too, and we’ll meet your needs with our turnkey roll cover solutions.

Need a roll cover for a groundbreaking new process? Our Technical Services team can design and formulate a cost-efficient roll cover that will get you to market faster. Want to return a decade-old roll to like-new condition? Our Mechanical Services team can repair and refurbish your roll and ship it back to you quickly without rush charges. And if you want to significantly improve the corrosion resistance of your roll journals and faces, cores and other parts, we can do that for you, too, with more than 300 thermal spray coating options. Contact us today to get started.