Diverse Industrial Solutions

Get long-term performance improvements for your specific roll cover needs.

No matter what your industry —architectural components, glass, food, leather, you name it — if your process requires rolling, Vail can custom formulate a roll cover that lasts longer, has fewer blowouts, is more reliable and offers greater cost savings.

To make sure you have the best roll covering for each position, we will come right to your plant to conduct a FREE, thorough analysis of your process. As an ISO certified company you can be sure the roll covers we deliver will conform to your stringent standards, too.

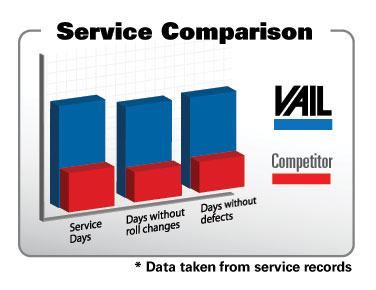

But don't come to us for the lowest initial roll cover price. Our industrial roll customers will tell you they pay three or more times more for a Vail roll cover. But they do it to save money. Once installed, these roll covers last up to five times longer! Our competition never talks about savings like that because they can't. Are you ready for that level of savings, too? Contact us.

Ongoing maintenance services further improve your processes and lower costs.

When your covers need refurbishing or your cores need repair, Vail's in-house Mechanical Service team will efficiently and cost-effectively conduct:

- Regrinding or recovering

- Grooving, threading and beveling covers

- Drill cleaning and drilling

- Complete core inspection

- In-house core repairs

- Millwright services

- New cores

- Rebuilding/reconditioning suction boxes

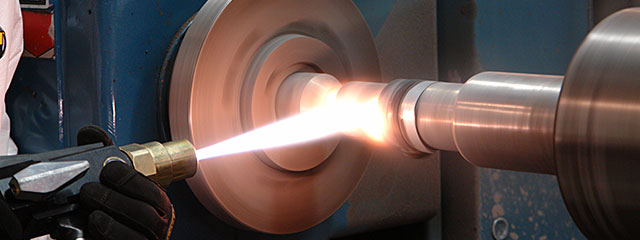

- Thermal spray coating for roll journals, cores and other equipment

- Roll cover maintenance and care seminars conducted at your site

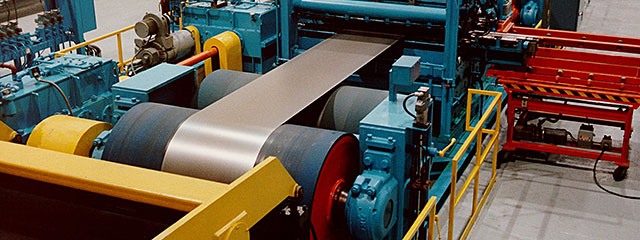

Metal Industry

Get the lowest total cost, not necessarily the lowest unit price.

Don't be fooled by others in our industry who try to convince you that driving down individual roll cover prices will give you breathing space in your operating budget. Our customers will tell you differently.

For example, one of our customers used to run a competitor's "economical" wringer roll cover. It was a "good buy." That is until Vail conducted a cost analysis of the process. We came back with a custom-formulated cover that was priced nearly four times higher than the competitor's cover. That's a big hit to anyone's bottom line. But our customer made the switch because Vail's custom roll cover ran seven times longer. It was more expensive per unit — but what a savings! No other roll cover manufacturer has been able to match Vail's lowest total cost performance in this application.

With Vail's expertise:

- Get longer running wringer, sink, steering, mechanical, bridle, hold down, deflector, pinch, pickling or furnace exit roll covers

- Custom formulate tougher mandrel sleeves, segments and fastening systems

- Protect your rolls and surface critical metals with polyurethane pads and products

- Remove liquids faster and easier with Masroll® rolls

- Use our ISO certification to help you meet the highest global standards, too.

Role Applications:

- Applicator/CoaterRolls

- Bridle Rolls

- Deflector Rolls

- Furnace Exit Rolls

- Hold Down/Ironing Rolls

- Mechanical Rolls

- Pinch Rolls

- Sink Rolls

- Steering Rolls

- Synchrowind Rolls

- Tension Leveler Rolls

- Wringer/Squeegee Rolls

To add these improvements to your operations (and bottom line), start with a FREE, onsite line inspection and roll analysis or contact us to talk specifics.

Download Current ISO Certification

Need repairs? Vail does the work to your specification, on time.

Even the best-formulated roll covers eventually wear out. So when you want your roll returned to like-new performance, contact Vail for:

- Regrinding or recovering

- Grooving, threading and beveling covers

- Drill cleaning and drilling

- Complete core inspection

- In-house core repairs

- Millwright services

- New cores

- Rebuilding/reconditioning suction boxes

- Thermal spray coating for roll journals, cores and other equipment

- Roll cover maintenance and care seminars conducted at your site

Our Products and Application Details

| Product | Properties | Application/Environment Detail |

|---|---|---|

| Z-Series™ | 50-95 Shore A hardness; 340°F max operating temp. | Resistant to high heat, cutting, tearing, wear, acids/caustics, oils, etc. |

| Ni-Chem™ | 60-90 Shore A hardness; 225° F max operating temp. | Resistant to abrasion & caustic solutions. |

| Orange Squeeze™ | 70-90 Shore A hardness; 225° F max operating temp. | Resistant to abrasion & acidic solutions. |

| PL Series™ | 80-95 Shore A Hardness; 225° F max operating temp. | Resistant to abrasion, cutting and chemcials including acids & oils. |

| DuraSqueeze XT™ | 70-90 Shore A hardness; 275°F max operating temp. | Excellent option for elevated temps, physical and chemical applications. |

| BlueCoat™ | 70-90 Shore A hardness; 275° F max operating temp. | Superior abrasion resistance and chemcial resistance. |

| Resistex™ | 60-80 Shore A hardness; 180° F max operating temp. | Resistant to HCL & general acids, good abrasion resistance. |

| BlackFire™ | 40-100 Shore A hardness; 225° F max operating temp. | Good in caustic, acidic and oily applications. Superior wear properties. |

| Core Guard™ | Approx. 75-80 Shore D hardness | Excellent resistance to cutting, used as a "hard base". |

| Thermodur™ | 60-70 Shore D; 2200 °F max operating temp. | Developed to transport sheet through furances of hot and cold rolling mills. |

| Polycast™ | 70-90 Shore A hardness; 160° F max operating temp. | Excellent cut/abrasion resistance in wet/humind environments. |

| Polycast+™ | 60 Shore A - 75 Shore D hardness; 180° F max operating temp. | Excellent abrasion/loading resistance in wet/humid environments. |

| Polylast™ | 30 Shore A - 60 Shore D hardness; 180° F max operating temp. | Ideal for heavily loaded mechanical applications, Good oil resistance |

| Polytek™ | 55-65 Shore A hardness; 180° F max operating temp. | Outstanding cut/tear/wear resistance for this hardness range. |

| Polyfire™ | 80 - 95 Shore A hardness; 250F max operating temp. | Excellent mechanical roll at higher temperatures |

| Nitrile | 40-100 Shore A hardness; 225° F max operating temp. | Interchangeable between caustics & acids. Excellent in oily applications. |

| CSM | 35-95 Shore A hardness; 275° F max operating temp. | Combination of temp, abrasion, chemical, and oil resistance. |

| EPDM | 30-95 Shore A hardness; 300° F max operating temp. | Resistant to chromic acid, caustics solutions, and weathering. |

| Neoprene | 20-95 Shore A hardness; 250° F max operating temp. | Very good resistance to acids, good abrasion resistance, versitile. |

| Viton | 70-90 Shore A hardness; 400° F max operating temp. | Excellent temp, oil, acid, caustic and solvent resistance. |

Paper Industry

Vail custom roll covers keep more money in your operations.

Let's face it. You rarely save money when you constantly recover your paper mill equipment rolls. That's why the lowest-priced roll cover isn't necessarily the "best buy." To really save money in your operations you need to significantly increase the run times between roll recovering. Come to Vail roll specialists for:

- Knowledge to help you improve your papermaking process without compromising your quality out-the-door

- Cost-control insight

- Custom rubber and special compound formulation expertise that last longer, perform better

- Dedicated field support and FREE onsite roll analysis

When you do need to repair or refurbish your rolls, no one offers more timely turnarounds than Vail.

Besides having no money to waste, you have no time to waste in the pulp and paper industry. So when your roll covers do need repairs or refurbishing, turn to our St. Joseph Service Center or Mobile Service Center. Our quality workmanship will earn your confidence and our timely deliveries your repeat business. Contact us whenever you need:

- Roll grinding

- General roll repair

- Suction roll rebuilds

- Headbox apron and top slice up refurbishment

- Variable crown rolls

- Spare parts

You may be familiar with our products under the following names:

| Tradename | Position |

|---|---|

| Insul 250 | Wire Rolls |

| Ebonite | |

| Black Rock | |

| Temp Rock | |

| Ni-Chem | Cylinder Couch |

| Ni-Chem X | |

| Couch Coat | |

| Poly-CC | |

| Top Tex | Extractor (110 P&J) |

| Near Rock | Drive Rolls |

| Vail-Mate II | |

| Long Lease I | Lumpbreaker |

| Long Lease | |

| Vail-Press I | Suction Press |

| Vail-Press II | |

| Drill Press | BD Press |

| Drill Press II | |

| Vail-Mate G II | Grooved Press |

| Vail-Mate G | |

| Emerald Stone | Hard Press |

| Emerald Stone II | Hard Size Press |

| Emerald Stone III | Hard Breakerstack |

| Top-Lease NIBR | Soft Press |

| Emerald-Mate | |

| Ultramate | |

| Emerald Mate | Soft Size Press |

| Emerald Mate | Soft Breaker Stack |

| Vail-Size | |

| Ultramate | |

| Maxcoat | Coater Rolls |

| Blue Coat II | |

| Blue Coat III | |

| Vail-Coat | |

| Poly-Cast Plus | Coater/Size Press |

| Silk Lease | Leadout/Leadin |

| Silk Lease II | |

| Silk Lease III | |

| Maxsize | Hard Size |

| Hard Breaker Stack | |

| Poly Dry | Dryer Felt Rolls |

| Vail-Therm |

|

| Reel Rock | Reel Spool |

| Polymate | |

| Chemshed | Sludge Press |

Industries

Vail rolls deliver more savings, more production, and more satisfaction.

If you are serious about saving money, optimizing your efficiency and increasing your overall productivity, turn to the roll cover experts at Vail Rubber Works, Inc. You can use our custom roll cover technologies and mechanical services to help you truly save money in your paper, metal or industrial applications.

To ensure you get real financial savings, ask our field support team to do a FREE, onsite analysis of your roll cover performance and its operating environment. Based on your data, we'll custom-formulate a long-lasting roll cover solution for your processes and do so at a competitive price.